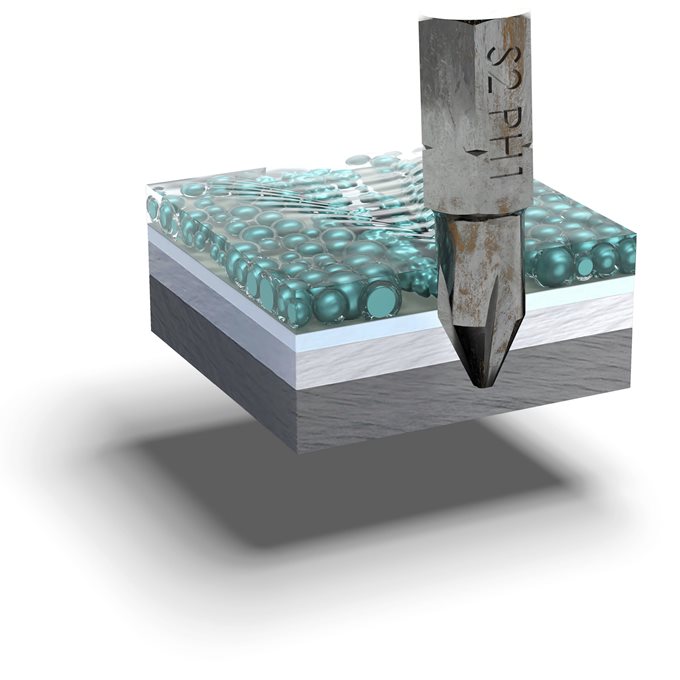

A surface with self-healing power? This is the MACO Evo effect. As with human skin, which heals injuries itself, nanocapsules incorporated into the surface act as a reservoir for lubricants and anti-corrosion substances.

If the surface is damaged during fitting assembly (e.g. by the cordless screwdriver), the substances contained in nanocapsules leak out and fill the scratches again – even before rust can develop. Or lubricate the surface under mechanical stress. This is unique in the industry.

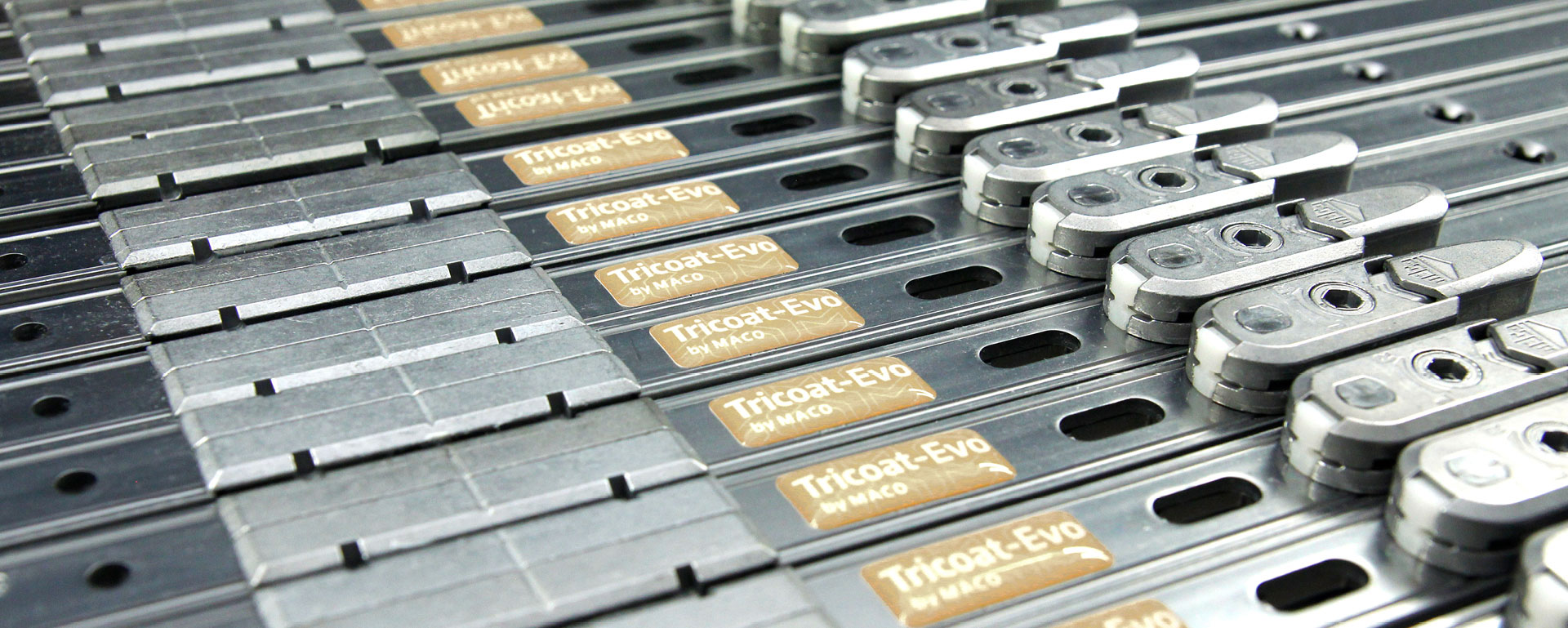

With this new generation and evolution in surface technology for the protection of fittings, we give you a further competitive advantage for your products.