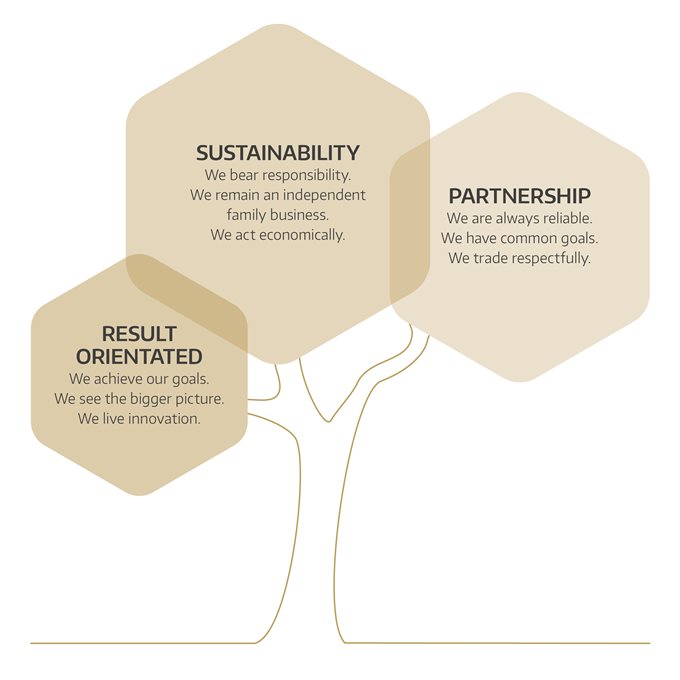

Shaping the future together: At MACO, we are determined to play an active role in shaping a sustainable future. As a construction supplier, we have a special responsibility. The trust that employees, customers and society place in us is both an inspiration and an obligation for us.

Our goal is clear: a liveable, sustainable society. To do this, we develop products and solutions that utilise natural resources in an innovative and efficient way. We want to be economically successful - but people and the environment have to be the winners.

That is why we think and act in terms of the circular economy: we produce responsibly, rely on sustainable raw materials, offer well-thought-out recycling processes and make targeted investments in renewable energies. This creates real added value - for everyone involved and for generations.

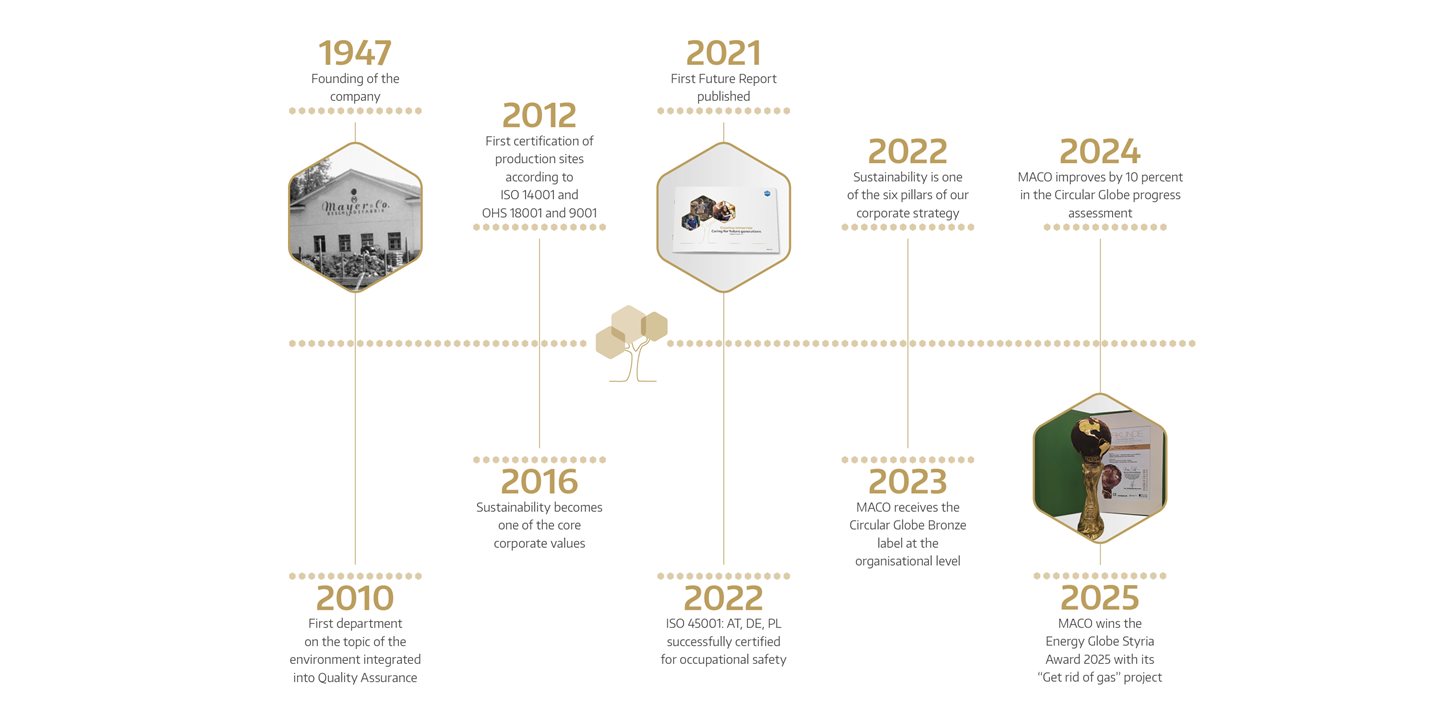

Being awarded the Circular Globe 2023/2024 and the Energy Globe 2025 confirms our path. We are determined to continue on this path - as the MACO Group and together with our employees, business partners and customers!

Creating Tomorrow

![]() In order to make this path transparent, we have been publishing our annual future reports since 2021: the current figures for 2024 can be found in the extended future report 2024/25. It shows how we harmonise progress and sustainability - with clear goals, measurable results and the conviction that responsible action today is the basis for a liveable tomorrow.

In order to make this path transparent, we have been publishing our annual future reports since 2021: the current figures for 2024 can be found in the extended future report 2024/25. It shows how we harmonise progress and sustainability - with clear goals, measurable results and the conviction that responsible action today is the basis for a liveable tomorrow.

Do you have questions & suggestions? We look forward to hearing from you: sustainability@maco.eu